دستگاه عیب یاب پیشرفته اولتراسونیک فیزره

دستگاه فیزره Olympus mx 2

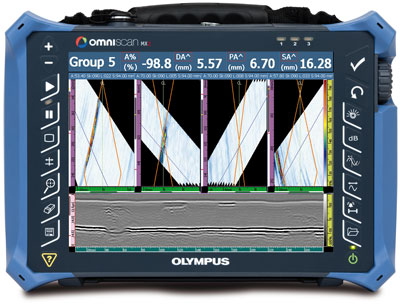

OmniScan MX2

Building on a Solid Basis

دستگاه فیزره Olympus mx 2

This second generation OmniScan MX2 increases testing efficiencies, ensuring superior manual and advanced AUT

application performance with faster setups, test cycles, and reporting, in addition to universal compatibility with all

phased array and ultrasound modules: past, present and future. Designed for NDT leaders, this high-end,

scalable platform delivers true next-generation NDT performance

The OmniScan MX2 offers a high acquisition rate and new powerful software features for efficient manual and

automated inspection performance-all in a portable, modular instrument

Design with NDT SetupBuilder

NDT SetupBuilder is a new PC-based software allowing to create inspection setup and visualize beam simulations

This software presents multiple features for easy, fast, and comprehensive inspection strategy elaboration

that can directly be imported in the OmniScan MX2

- Wedge and probe selection can be carried out within the Olympus part database

- Instantaneously simulate beams trajectory in the material

- Visualize and adjust the part, probe, weld, and beams in different views, such as: side, end, top, or 3D

- Represent most commonly inspected materials and parts such as plates, and circumferential or axial welded pipes

- Copy and flip existing groups for quick multiple probe configurations

Setup with

The most efficient way to create a setup is to perform the simulation in NDT SetupBuilder, and import it directly to the OmniScan.

Afterward, only a few operations such as gate and range settings, are required in the OmniScan prior to starting the acquisition.

However, with its automatic probe recognition capability the OmniScan MX2 can also be used to create a complete setup using the following features:

- Intuitive wizards to guide the user through every step of the setup creation using the interactive help menu

- Weld Overlay and RayTracing simulation

- Group copy option for fast multiple group configuration

Aquire with Omniscan MX2

Thanks to its new partners, NDT SetupBuilder and OmniPC, the OmniScan MX2 can be used to perform all

steps required for the inspection directly on its large touch screen or be dedicated to calibration and acquisition tasks.

Calibration

The Calibration Wizard ensures that every focal law in every group is the direct equivalent of a single-channel

conventional flaw detector for compliance to codes. The user is guided step-by-step through Velocity, Wedge Delay,

Sensitivity, TCG, DAC, AWS, and encoder calibrations.

TOFD PCS calibration and lateral wave straightening can now be performed automatically

Acquisition

The OmniScan MX2 enables easy configuration of inspection parameters for either manual, or one-line, raster, or helicoidal encoded scans.

The acquisition is displayed in real time and offers the ability to rewrite data that can be stored within full A-scans,

S-scans, and/or C-scans on a hot-swappable SD card or USB 2.0 device

- Different gate-synchronization capabilities

- New, intelligent layouts for configuring up to 8 groups

- Full-screen mode for visualization at greater distance

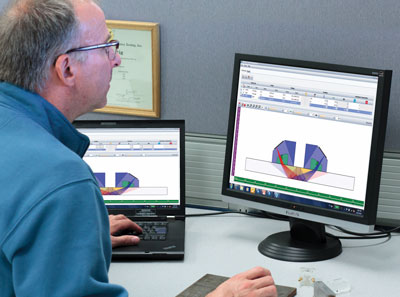

Data Analysis with OmniPC

OmniPC is a new software program that benefits form the same user interface and analysis and reporting

features as the OmniScan with the added flexibility to be run on a personal computer.

With OmniPC, the OmniScan unit can now be used strictly for scanning while analysis is performed

simultaneously on a personal computer. This software can also be used in conjunction with extra large screens

for increased visibility, and with keyboard shortcuts for faster operations.

Data Analysis with OmniScan MX2

- Data, reference, and measurement cursors for defect sizing

- Extensive Readings database and predefined lists for trigonometry, flaw statistics on axes, volumetric position information, code-based acceptance criteria, corrosion mapping statistics, etc.

- Views are linked for interactive analysis and automatically updated when performing off-line gate repositioning.

- Optimized preconfigured layouts for quick and simple length, depth, and height sizing of flaws.

Reporting

The OmniScan MX2 and OmniPC can both be used to generate reports with an indication table

listing up to eight readings, such as amplitude, position, and size of the defects.

The report can also be customized with additional readings and comments specific to each indication,

and can be saved as an HTML document. RayTracing tools allow the indication positions to be represented

on the weld profile. High-resolution images can be inserted along with all relevant inspection parameters

The OmniScan MX2 is an important part of your inspection solution, and can be combined with other critical

components to form a complete inspection system. Olympus offers a complete product range that includes

phased array probes, scanners, analysis software, and accessories, all of which are integrated and

packaged into rapidly deployable, application-specific solutions for quick returns on your investment.

In addition, Olympus offers a high-quality calibration and repair service worldwide, that is backed by a

team of phased array application experts to ensure that you get the support you need.

|

|

|

|

|

Pressure Vessel Weld Inspection

جهت مشاوره و دریافت پیش فاکتور و مطلع شدن از دیگر تجهیزات وابسته به این دستگاه لطفا با کارشناسان واحد فروش شرکت پترو پژوهش تماس حاصل فرمائید PPKGROUP.CO |

Composite Inspection Olympus offers complete solutions for the inspection of carbon-fiber-reinforced polymer structures. These solutions are based on the OmniScan flaw detector, the GLIDER™ scanner, and dedicated probes and wedges designed for CFRP flat panel and radius inspection. |

Weld Inspection of Small-Diameter Pipes When coupled with the COBRA manual scanner, the OmniScan flaw detector is capable of inspecting pipes ranging from 0.84 inch OD to 4.5 inch OD. With its very slim design, this manual scanner is able to inspect pipes in areas with limited access. |

Corrosion Mapping Inspection The OmniScan PA system with the HydroFORM scanner is designed to offer the best inspection solution for the detection of wall-thickness reductions resulting from corrosion, abrasion, and erosion. For this application, phased array ultrasound technology offers superior inspection speed, data point density, and detection. |

دستگاه فیزره Olympus mx 2

021-77130687-8

021-77228679